MTBF Calculation Definition

Introduction

Reliability is a topic in which there are many misconceptions due to a misunderstanding or misuse of the basic language. It is therefore important to get an understanding of the basic concepts and terminology in order to communicate its concepts more clearly. A practical definition of reliability is “the probability that a piece of equipment operating under specified conditions perform its basic function for a stated period of time”. The reliability is a statistical probability defined as a number between 0 and 1 representing the chances of a successful outcome.

Failure rate

All products have a failure rate, which is simply the number of units failing per unit time. The failure rate is usually represented in reliability mathematics by the Greek symbol Lambda (λ). The failure rate of a product may change throughout the life of the product. This is what gives us the familiar Reliability bathtub curve shown in the upper left, which shows the failure rate vs. operating time for a product. The bathtub curve is widely used in reliability engineering. It describes a particular form of the hazard function which comprises three parts:

- The first part is a decreasing failure rate, known as early failures.

- The second part is a constant failure rate, known as random failures.

- The third part is an increasing failure rate, known as wear-out failures.

MTBF vs. MTTF

It is commonly misunderstood and assumed that the MTBF (mean time between failures) indicates a minimum, guaranteed time before failure occurs. Technically, MTBF (mean operating time between failures) applies to equipment that is going to be repaired and returned to service, MTTF (mean time to failure) applies to equipment that will not be repaired but discarded after failure. For simple systems these terms are often used interchangeably and only in very complex systems is the distinction significant.

Constant Failure Rate

During the constant failure rate portion of the Reliability bathtub curve, MTBF is the inverse of the failure rate. If the failures occur randomly as in the constant failure rate portion of the curve then they can be described by the exponential distribution. When the operating time equals the MTBF the reliability becomes 37% by definition. This can be stated in several ways:

- For a single unit, the probability that it will work for as long as its MTBF, is 37%.

- For a single unit, the probability that it will fail before its MTBF, is 63%.

- If a population of units is considered, then 37% of them will be functioning at the MTBF, while 63% of the population will have failed.

Non-Constant Failure Rate

During the decreasing failure rate and the increasing failure rate or wear-out portions of the Reliability bathtub curve, the failure rate is not constant. The reliability of these times in a system’s life requires different analysis tools other than the simple concept of MTBF / MTTF.

For the exponential failure distribution, the hazard rate is a constant with respect to time (that is, the distribution is "memory-less"). For other distributions such as a Weibull distribution or a log-normal distribution, the hazard functions are not constant with respect to time.

A continuous failure rate depends on the existence of a failure distribution, which is a cumulative distribution function that describes the probability of failure up to and including the time of failure. A widely used failure distribution in reliability engineering is the Weibull distribution because of its ability to describe either an increasing or decreasing failure rate.

About MTBF Prediction Standards

Reliability Predictions

Reliability Predictions like those in MIL-HDBK-217 and Telcordia standards are commonly used by reliability engineering in the development of products and systems to compare alternative design approaches and to assess progress toward reliability design goals. MIL-HDBK-217 Predictions are a valuable form of analysis that provides insight into safety, maintenance and warranty costs and other product considerations.

MIL-HDBK-217 "Reliability Prediction of Electronic Equipment" - Even though MIL-HDBK-217 handbook is no longer being kept up to date by the US military, it remains the most widely used approach by both commercial and military analysts.

Bellcore (now Telcordia) TR-332 - The Bellcore approach is widely used in the telecommunications industry and has been recently updated to SR-332 in May 2001. It is very similar to MIL-HDBK-217.

The IEEE Gold Book - IEEE STD 493-1997, IEEE Recommended Practice for the Design of Reliable Industrial and Commercial Power Systems, provides data on commercial power distribution systems.

NSWC-94/L07 - Handbook of Reliability Prediction Procedures for Mechanical Equipment. This handbook presents a unique approach for prediction of mechanical component reliability by presenting failure rate models for fundamental classes of mechanical components.

MIL-HDBK-217

MIL-HDBK-217 has been the mainstay of reliability predictions for years. The MIL-HDBK-217 handbook includes a series of empirical failure rate models developed using historical piece part failure data for a wide array of component types. There are models for virtually all electrical/electronic parts and a number of electromechanical parts as well. All MIL-HDBK-217 models predict reliability in terms of failures per million operating hours and assume an exponential distribution (constant failure rate), which allows the addition of failure rates to determine higher assembly reliability. The MIL-HDBK-217 handbook contains two prediction approaches: the parts stress technique and the parts count technique and covers 14 separate operational environments, such as ground fixed, airborne inhabited, etc. As the names imply, the parts stress technique requires knowledge of the stress levels on each part to determine its failure rate, while the parts count technique assumes average stress levels as a means of providing an early design estimate of the failure rate.MIL-HDBK-217 reliability predictions are also usually a reliability analyses requirement for all Military project proposals.MIL-HDBK-217 reliability predictions are a type reliability analysis which provides a reliability calculation method to determine the MTBF of a project. It provides a how to calculate MTBF using a standardized reliability analysis method according to Mil Standards

Bellcore's or Telcordia TR-332

Bellcore's (now Telcordia) TR-332, approach is very similar to that of MIL-HDBK-217 but it's based primarily on telecommunications data and covers five separate use environments. The Telcordia standards approach also assumes an exponential failure distribution and calculates reliability in terms of failures per billion part operating hours, or FITs. Telcordia standards empirically based models are in three categories: the Method I parts count approach that applies when there is no field failure data available, the Method II modification to Method I to include lab test data and the Method III variation that includes field failure tracking. For the most widely used Telcordia standards Method I case where the burn-in varies, the steady-state failure rate depends on the basic part steady-state failure rate and the quality, electrical stress and temperature factors.Telcordia standards reliability predictions are a type reliability analysis which provides a reliability calculation method to determine the MTBF of a project. Telcordia standards provide a how to calculate MTBF using a standardized reliability analysis method according to Telcordia Standards.

NSWC-94/L07 & L11

NSWC-94/L07 & L11 - Handbook of Reliability Prediction Procedures for Mechanical Equipment. This handbook, developed by the Naval Surface Warfare Center –provides failure rate models for fundamental classes of mechanical components. Examples of the specific mechanical devices addressed by the document include belts, springs, bearings, seals, brakes, slider-crank mechanisms, and clutches. Failure rate models include factors that are known to impact the reliability of the components. For example, the most common failure modes for springs are fracture due to fatigue and excessive load stress relaxation. The reliability of a spring will therefore depend on the material, design characteristics and the operating environment. NSWC-94/L07 & L11 models attempt to predict spring reliability based on these input characteristics.

IEEE Gold Book

The IEEE Gold Book provides data concerning equipment reliability used in industrial and commercial power distribution systems. Reliability data for different types of equipment are provided along with other aspects of reliability analysis for power distribution systems, such as basic concepts of reliability analysis, probability methods, fundamentals of power system reliability evaluation, economic evaluation of reliability, and cost of power outage data.

More Information

The most widely known and used reliability prediction handbook is MIL-HDBK-217. It is used by both commercial companies and the defense industry, and is accepted and known world-wide. The most recent revision is “Military Handbook, Reliability Prediction of Electronic Equipment”, MIL-HDBK-217, Revision F, Notice 2, which was released in February of 1995. It contains failure rate models for numerous electronic components such as integrated circuits, transistors, diodes, resistors, capacitors, relays, switches, and connectors. MIL-HDBK-217 requires a greater amount data entered into the model. It also is a little harsher in the calculation of failure rate data than the Bellcore standard. Typically, but not always, MIL-HDBK-217 calculated results will show a higher failure rate than Bellcore standard for the same system. This difference in the standards obviously stems from the original intended use of the MIL-HDBK-217 standard for aerospace and military, or mission critical applications.

Maintaining reliability and providing reliability engineering is an essential need with modern electronic systems. Reliability engineering for electronic equipment requires a means for a quantitative baseline, or a reliability prediction analysis. The MIL-HDBK-217 standard was developed for military and aerospace applications; however, it has become widely used for industrial and commercial electronic equipment applications throughout the world. Using the MIL-HDBK-217 standard for reliability prediction produces calculated Failure Rate and Mean Time Between Failures (MTBF) numbers for the individual components, equipment and the overall system. The final calculated prediction results are based on the roll-up, or summation, of all the individual component failure rates.

“Military Handbook; Reliability Prediction of Electronic Equipment”, MIL-HDBK-217F Notice 2 dated December 2, 1991 developed by Rome Laboratories, and the United States Department of Defense. The purpose for developing this handbook was to establish and maintain consistent and uniform methods for estimating the inherent reliability of military electronic equipment and systems. The handbook is intended as a guideline, not a specific requirement, to increase the reliability of equipment being designed.

The MIL-HDBK-217 handbook contains two prediction approaches: the parts stress technique and the parts count technique and covers 14 separate operational environments, such as ground fixed, airborne inhabited, etc. As the names imply, the parts stress technique requires knowledge of the stress levels on each part to determine its failure rate, while the parts count technique assumes average stress levels as a means of providing an early design estimate of the failure rate. MIL-HDBK-217 reliability predictions are also usually a reliability analyses requirement for all Military project proposals. MIL-HDBK-217 reliability predictions are a type reliability analysis which provides a reliability calculation method to determine the MTBF of a project. It provides a how to calculate MTBF using a standardized reliability analysis method according to Mil Standards.

Part Stress Analysis

The Part Stress Analysis method is used the majority of time and is applicable when the design is near completion and a detailed parts list, or BOM, plus component stresses are available. By component stresses, the standard is referring to the actual operating conditions such as environment, temperature, voltage, current and power levels applied, for example. The MIL-HDBK-217 standard groups components or parts by major categories and then has subgroups within the categories. An example is a “fixed electrolytic (dry) aluminum capacitor” is a subcategory of the “capacitor” group. Each component or part category and it's subgroups have a unique formula or model applied to it for calculating the failure rate for that component or part.

Environment

Environmental stress is of major concern in establishing the failure rate for components and parts included in a system per the MIL-HDBK-217 model. Environmental stresses can be quite different from one application environment to another and can subject the equipment to a controlled environment with constant temperature and humidity, or an environment with rapid temperature changes, high humidity, high vibration and high acceleration, for example. The environmental designations included within MIL-HDBK-217 are included in the formulas as piE,

Thermal Environment

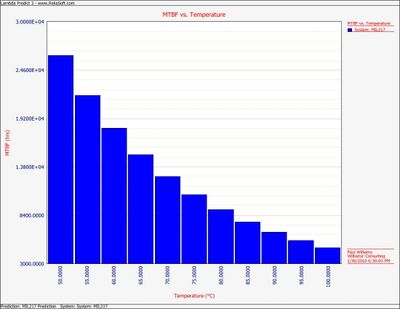

Ambient and operating temperatures have a major impact on the failure rate prediction results of electronic equipment, especially equipment involving semiconductors and integrated circuits. The MIL-HDBK-217 standard requires an input of ambient temperatures and more definitive data required for the calculation of junction temperatures in semiconductors and microcircuits.

MIL-HDBK-217 Parts Count Analysis

The MIL-HDBK-217 Parts Count Reliability Prediction it normally used when accurate design data and component specifications are not determined. Typically, this will happen during the proposal and bid process or early in the design process. However, this stage in the design process is where design decisions and project specifications, allocations, etc. can be determined with help from preliminary reliability prediction data. (Refer to the MIL-HDBK-217 standard for the specific equation)

The MIL-HDBK-217 standard provides tables for the component groups (same groups as the Parts Stress analysis) listing generic failure rates and quality factors for the different MIL-HDBK-217 environments.

Copyright © 2023 MTBFReport.com - All Rights Reserved.

Powered by GoDaddy